S400光柵漫反射型近紅外儀器產品參數

儀器用途: 本儀器是種光柵型漫反射NIRS,應用廣泛主要用于對粉末、顆粒狀及涂層等樣品的化學、物理性質作定性定量分析,適用于對農產品、食品、醫藥等領域的營養成分、水分等化學物理性質的快速無損分析測定。特點:● 獲兩項國實用新型專利● 采用光柵譜掃描● 旋轉式樣品臺,解決樣品混合不均勻問題● 原裝進口硫化鉛檢測器帶制冷● 積分球反射率95%以上● 采用非球面光路,交叉CT單色器● 串行口外接高檔筆記本PC● 儀器小型輕巧,方便用于現場測試● 采用中國農業大學近紅外開發研究室的CAUNIRS近紅外分析軟件● 公司與中國農業大學近紅外研究室合作,● 為用戶提供、專業的近紅外建模及模型維護服務儀器性能:● 波長范圍:1300 nm~2500 nm● 波長掃描間隔:4、8、16 nm可選● 波長準確性:≤1nm● 波長重復性:≤1nm● 吸光度重復:0.002A● 信噪比:≥103● 掃描時間:少于2分鐘● 圓形樣品池規格:40mm內徑 × 20mm深度

TRI-TRONICS公司光柵編碼器

R20, R20-P, RG, RJ, RL, RL-P, RS, RS-P Series Shaft encoders are intended for direct coupling to a device shaft, and generate a specific pulse output for each revolution of the device shaft....

Series 20 with Heavy Duty BearingsThe model R20 is an optical shaft encoder in a 2" diameter x 1-3/4" long housing that can be face mounted using three 6-32 x .25" deep mounting holes on a 1.75" diameter bolt circle. The shaft is up to 3/8" diameter, either single or double ended. Electrical connection is through a 16mm circular connector or an attached cable.

Standard Features and Options:

- 3/8" diameter shaft

- Unbreakable code disk

- Up to 1200 pulses per revolution

- Attached cable or optional connector

- Heavy Duty bearings

- Short circuit and ESD protected

Popular Models:

R20CQ-500/5 M187R20CQ-500/8-30CSR20M8-200/5-26R20Q-1200/5-26DGS RCR20Q-512/24PR20Q-512/8-30DL M222B

Series 20-P with Heavy Duty BearingsThe model R20-P is an optical shaft encoder in a 2" diameter x 1-3/4" long housing that can be face mounted using three 6-32 x .25" deep mounting holes on a 1.75" diameter bolt circle. The shaft is up to 3/8" diameter, either single or double ended. Electrical connection is through a 16mm circular connector or an attached cable.

The encoder is factory configured with a program that offers one or more features. DIP switches are used to set program parameters. Examples of some of the available features are: selectable pulses per revolution, quadrature (A/B) outputs, direction output, and the anti-jitter feature.

Standard Features and Options:

- DIP switch sleectable features

- Up to 3/8" shaft diameter, option double ended

- Heavy Duty bearings

- Unbreakable code disk

- Size 20 housing

- Short circuit and ESD protected

- Up to 1200 pulses per revolution

- Attached cable, or 16mm or M12 connector

Popular Models:

R20-P64AJ/8-30S

RG - General Purpose and EconomicalA 2.25" diameter incremental encoder with three 6-32 x .25" deep mounting holes on a 1.75" diameter bolt circle. The enclosure is 1.75" long when equipped with an attached 10 ft. (3 meter) cable, or 3" long with a connector.

Standard Features and Options:

- Short-Circuit and ESD protection are available on allm odesl with the anti-jitter option, and many other (please inquire)

- Surge protection available

- CE Marked (specific models only and requires end or side connector)

- 10-foot / 3-meter attached cable is included at no extra charge.

Popular Models:

RGA-2400/24NPRGA-600/12RGA-600/5RGAQ-10/12 M49RGB-1200/24RGB-240/8-30CERGBQ-240/24CERGBQZ-1200/8-30ERGBQZ-360/24P

General Purpose and Environmentally Sealed

A 2.25" diameter incremental encoder with three 6-32 x .25" deep mounting holes on a 1.75" diameter bolt circle. The enclosure is 3" long with a side connector or end connector. Many modified versions match ECCI encoders.

See the RG encoder for an economical version that is not environmentally sealed.

Standard Features and Options

- Shaft: 3/8" x 3/4" length

- Short-Circuit, ESD, and Surge protection are available

- CE Marked (specific models only)

Popular Models:

RJB-3AJ/24PRJBQ-120/12 M76RJBQ-300/5 M76RJBZ-2400/8-30NPRJM8QZ-500/8-30NP M247SRJQ-100/5 M125RJQ-250/5 M125RJQ-600/5 M125RJQNZ-500/5 M92

RL General Purpose and Heavy DutyThe model RL rotary shaft encoder comes with a 3/8", 1/2", 5/8", 8mm, 10mm, or 3/8-16 or 1/4-20 threaded shaft for heavy duty applications where a face mounted encoder is required. The rugged 3" diameter by 2-3/8" deep enclosure is constructed of 1/4" thick aluminum with a 5, 6, or 10 pin connector on the side.

Metric bolt holes are available - see M96 and M105 modifications below.

***Optional modification number (see modified versions table below)***For other accessory options, see the accessories table below

Notes: * 120AC supply voltage and Triac output require the 3/8" single or double ended shaft.

Note: Not all features are listed. Some combinations are mutually exclusive.

Standard Features and Options- Shaft: 3/8" x 1.25" length, single or double ended. 1/2" x 1.25" length. 5/8" x 1.25" length. 8mm x 32mm. 10mm x 32mm.

- Short-Circuit, ESD, and Surge protection are available

- CE Marked (specific models only)

The RL-P rotary shaft encoder directly couples to a rotating shaft and produces a specified number of square wave output pulses per revolution of the shaft. The number of pulses per revolution is determined by setting configuration switches accessible through an access port near the connector. Any one of a predefined set of pulses per revolution are available.

It comes with a 3/8", 1/2", 5/8", 8mm, 10mm, or 3/8-16 or 1/4-20 threaded shaft for heavy duty applications where a face mounted encoder is required. The rugged 3" diameter by 2-3/8" deep enclosure is constructed of 1/4" thick aluminum with a 5 or 6 pin connector on the side.

Metric bolt holes are available - see M96 and M105 modifications.

Standard Features and Options:

- Heavy duty bearings

- 3/8", 1/2", 5/8", Metric Shaft Diameters

- Double ended 3/8" shaft option

- Hollow shaft available - Model HRL-P

- Use DIP switches to configure options at installation time

- User selectable pulses per revolution

- User selectable output circuit

- Exclusive "Anti-Jitter" option

- Short-circuit and ESD protection

- 5 vdc, or 8 to 30 vdc supply voltages

- 1, 2, and 3 output models available

- Fully interchangeable with model RL

Popular Models:

RL-P240AJ/8-30RL-P270AJB/8-30RL-P64AJ/8-30

RS Standard 2-1/4" Cube Style EncoderA 2-1/4" cube incremental encoder with four 6-32 x 1/4" deep mounting holes on a 2" diameter bolt circle located on both ends and the bottom. The enclosure is constructed of 1/8" minimum thick aluminum with a connector and single or double ended shaft. This model is compatible with most cube style encoders on the market.

It is available with 1/4", 5/16", 3/8", or 1/2" shaft diameters. Heavy duty bearings are available with up to 3/8" single ended shaft (see M182 option).

Standard Features and Options:

- 1/4", 5/16", 3/8", and 1/2" Shaft Diameters

- Double ended shaft option

- Hollow Shaft Available (see model HRS)

- Programmable model availabe (see model RS-P)

- Exclusive "Anti-Jitter" circuit for conveyor applications

- Single (A), Quadrature (A,B) and Index (Z) outputs

- Dual or Triple output Models with different pulses per revolution on each output (A, B, C)

- Short ciruit / ESD protection on most models.

- Custom Model Available

Popular Models:

RS.5-500/8-30 M166RS.5Q-500/8-30 M166RSAQ-100/10/15CRSB-100/5 M122RSB-10AJ/8-30PRSB-12/8-30P RSB-1200/8-30RSB-2400/5RSB-3/6/8-30 M88RSB-5/10/8-30 M88RSB-5AJ/24PRSB-6AJ/8-30RSBD-235/12RRSBD-300/12RRSBD-80/12R RSBDQ-100/8-30RSBDQ-250/5 M122RSBQ-100/8-30RSBQ-100/8-30PRSBQ-1000/8-30RSBQ-1200/8-30DLRSBQ-30/8-30RSBQ-512/8-30RSC-10/8-30C M214RSC-100/8-30C M214RSC-60/8-30 M143

RS-P User Selectable Pulses per Revolution in a Standard Cube StyleThe model RS-P is an optical shaft encoder in a standard 2¼” cube shaped housing that is electrically and physically interchangeable with most cube style encoders on the market. The number of pulses per revolution is determined by setting configuration switches accessible through an access port near the connector. Any one of a predefined set of pulses per revolution are available.

Standard Features and Options- Short-Circuit and ESD protection are standard

- Surge protection is available

- CE Marked

Popular Models:

RSBD-P64Q/8-30 M172RSB-P.125A/8-30RSB-P.125AJ/8-30RSB-P240AJ/8-30RSB-P64AJ/8-305RSB-P64AJ/8-30CRSB-P64AJ/8-30G

Hollow shaft encoders are designed with either a through-bored shaft or a blind-bored shaft, and intended to mount directly onto a motor or other shaft. This eliminates the need for a shaft to shaft coupling and mounting adapter, resulting in both space and cost savings. The encoder "floats" on the motor shaft. A tether or flexible mounting bracket prevents the encoder from turning, yet accommodates shaft-to-shaft misalignment.An incremental encoder that uses precision measuring wheels to directly measure the movement of a conveyor belt, or to accurately measure moving material.

HS20 - Up to 5/8" / 16mm Diameter Hollow ShaftThe model HS20 is an optical hollow shaft encoder in a 2" diameter housing that mounts directly on an existing shaft assembly. A flexible mounting bracket or tether allows the encoder to float on the shaft without rotating. The HS20 generates up to 3 square wave outputs.

Standard Features and Options:

- Up to 5/8" or 16mm shaft bore

- Unbreakable code disk

- Up to 1200 pulses per revolution

- Attached cable or optional connector

- Heavy duty bearings

- Short circuit and ESD protected

Popular Models:

- HS20.405-5AJ/8-30S M210

- HS20.5QZ-1200/8-30

- HS20.625-100AJ/8-30S3

- HS20.625Q-1000/8-30DS

- HS20.625Q-256/8-30DS

- HS20.625Q-32/8-30DS

- HS20.625Q-600/8-30D

- HS20.625Q-64/8-30DS

- HS20.625Q-64/8-30DS M203

- HS20.625QZ-360/5S

- HS20B-1200/8-30S

- HS20BQ-120/5D

- HS20BQ-1200/8-30S

- HS20M10-5AJ/8-30 M203

- HS20M10-5AJ/8-30S3 M203

- HS20M12Q-50/8-30DS

- HS20M14QZ-125/5C

- HS20M14QZ-35/8-30C

- HS20M8Q-1000/8-30

The model HS25 is an optical hollow shaft encoder in a 2-1/2" diameter housing that mounts directly on an existing shaft assembly. An anti-rotation pin or flexible mounting bracket allows the encoder to float on the shaft without rotating. The HS25 generates up to 3 square wave outputs.

Standard Features and Options:

- Up to 3/8" or 10mm shaft bore diameter

- Up to 600 pulses per revolution

- Single, quadrature, and index outputs

- Direction indicator output option

- Anti-jitter feature option

- ESD and short circuit protection on most models

- 5 vdc, 8 to 30 vdc, and other supply voltages

- 9-pin D-Sub or 4-pin M12 connector

Popular Models:

- HS25B-1000/8-30

- HS25B-10AJ/24P

- HS25B-1200/24

- HS25B-1200/8-30

- HS25B-240/8-30

- HS25B-600/24

- HS25B-600/8-30

- HS25B-920/8-30C

- HS25BQ-240/24

- HS25BQZ-360/5C

- HS25CQ-360/3/8-30C M158 M179

The model HS30 is an optical hollow shaft encoder in a 3" diameter housing that mounts directly on an existing shaft assembly. A flexible mounting bracket or tether allows the encoder to float on the shaft without rotating. The HS30 generates up to 3 square wave outputs.

Standard Features and Options:

- Up to 1/8" or 28mm shaft bore

- Unbreakable code disk

- Up to 1200 pulses per revolution

- Attached cable or optional connector

- Heavy duty bearings

- Short circuit and ESD protected

Popular Models:

- HS30.5Q-500/5S1

- HS301.0Q-16/8-30DS

- HS301.125QZ-1200/8-30DS1

- HS30M25Q-600/8-30

- HS30M25QZ-360/8-30

- HS30M25QZ-360/8-30S

The model HRL is an optical hollow shaft encoder with up to a 1" / 25mm blind shaft bore in a heavy duty aluminum style housing that mounts directly on an existing shaft assembly. A flexible mounting bracket or tether allows the encoder to float on the shaft without rotating. The HRL generates up to 3 square wave outputs.

Standard Features and Options:

- 10-foot / 3-meter cable included at no extra charge

- CE Marked

- Surge protection available

- Short circuit and ESD protected

Popular Models:

- HRL.625-436/8-30C M162 M164

- HRL1-168/5 M180

- HRL1-360/24

- HRL1Q-200/12C

The model HRS is an optical hollow shaft encoder with up to a 1" / 25mm blind shaft bore in a standard 2-1/4" cube style housing that mounts directly on an existing shaft assembly. A flexible mounting bracket or other type of tether allows the encoder to float on the shaft without rotating. The HRS generates up to 3 square wave outputs.

Standard Features and Options:

- CE Marked

- Surge protection available

- Short circuit and ESD protection are available on most models with the anit-jitter option, and many others (please inquire)

A single-turn, absolute encoder generates a multi-bit binary code word indicating the angular position of the shaft. Each equal sized segment of one shaft rotation is indicated by a unique value. When power is first applied the shaft position is immediately known without having to re-home, even if the shaft is moved when power is off.

The MR30 is a full function 11-bit, single-turn, digital, absolute position encoder for applications requiring up to 1024 uniquely identifiable codes per revolution. It uses a patented, cost saving technology that relaxes the precise alignment tolerances typically required by conventional absolute encoders by an order of magnitude without sacrificing accuracy. This makes possible a low cost, modular encoder that can be easily assembled by the user.

The Photocraft SR12 is a full function, 10-bit, single-turn, digital, rotary absolute position encoder intended for applications requiring miniature size, low cost, and up to 1024 uniquely identifiable positions per revolution. The SR12 outputs the position information in either digital parallel or serial formats, or 0-10vdc analog format. In analog format the SR12 can function as a non-contact potentiometer.

The R30 is a 10-bit, single-turn, digital, rotary absolute position encoder intended for industrial applications requiring up to 1024 uniquely identifiable positions per revolution. The SR30 provides up to 10-bits and uses a patented, cost saving technology that relaxes the precise alignment tolerances of conventional absolute encoders by an order of magnitude without sacrificing accuracy. The result is a fully functional, yet lower cost alternative. The SR30 updates the outputs at 1KHz and the SR31 updates at 3KHz.

Wheeled encoders more accurately track the conveyor belt or other material than shaft encoders. Two problems with shaft encoders in this application are: (1) slippage of the conveyor belt on the roller, and (2) inaccuracy of roller diameters. Both of these contribute to inaccuracies that reduce the overall efficiency of a material handling sortation system or precision measuring system. Wheeled encoders ride directly on the moving material, use a wheel tread having a high coefficient of friction, and have a very low starting torque resulting in virtually no slippage of the wheels on the belt. In addition, the wheels are precision ground with exacting tolerances, versus a roller which has a much larger tolerance and its circumference seldom translates into an integral number of encoder pulses per unit of linear movement.

- R21-1000/8-30C

- R21-16AJ/8-30S3

- R21QZ-1024/5DS

- R21-P144AJ/8-30S

- R22-1000/5DS M233

- R22-1200/5 M189

- R22Q-1000/8-30S3

- R22Q-1200/5DS M233

- R22Q-1200/5DS

- R22Q-1500/8-30S3

- R22Q-800/8-30S M203

- R22QZ-1200/5-26DHS

- R22QZ-1200/5DLS

- R22-P1200QB/5-26DHS

- R22-P1200QR/5DLS

- R22-P64AJ/8-30S

- RH-10AJ/120ACT

- RH-12/12

- RH-12/12P

- RH-1200/8-30NP

- RH-12AJ/12

- RH-12AJ/24P

- RH-12AJ/8-30

- RH-192/12C

- RH-192/12C M148

- RH-192AJ/8-30P M131

- RH-1AJ/120ACT

- RH-2/24P

- RH-24/8-30C

- RH-240AJ/8-30C,120AJ/8-30C M154

- RH-24AJ/12C

- RH-2AJ/120ACT

- RH-2AJ/24P

- RH-2AJ/8-30P

- RH-300/5

- RH-3600/8-30

- RH-3AJ/120ACT

- RH-3AJ/24C

- RH-3AJ/24P

- RH-4/24P

- RH-4AJ/120ACT

- RH-4AJ/24

- RH-4AJ/24P

- RH-6/24P

- RH-600/8-30

- RH-600AJ/5-26P

- RH-6AJ/12

- RH-6AJ/120ACT

- RH-6AJ/24

- RH-6AJ/24P

- RH-6AJ/8-30

- RH-8AJ/24C IW

- RHQ-100/24P

- RHQ-1000/24C

- RHQ-1000/24P

- RHQ-1024/5D

- RHQ-1200/24P M131

- RHQ-1200/5 -30

- RHQ-1200/8-30NP

- RHQ-256/8-30D

- RHQ-360/15C

- RHQ-50/24

- RHQ-50/24RD

- RHQ-600/5D

- RHQ-72/5

- RH-P144AJ/8-30 IW

- RH-P144AJ/8-30 M126

- RH-P144AJ/8-30 M131

- RH-P144AJ/8-30

- RH-P144AJ/8-30 RC M202

- RH-P1500AJB/8-30 M131

- RH-P1500AJB/8-30

- RH-P1500QB/8-30 M218

- RH-P1500QB/8-30

- RH-P192/8-30 M196

- RH-P240AJ/8-30

- RH-P240AJ/8-30 IW

- RH-P240AJ/8-30 M131

- RH-P240AJ/8-30 M148

- RH-P240AJ/8-30

- RH-P240AJ/8-30 RC

- RH-P240Q/8-30

- RH-P300AJQ/8-30C

- RH-P600AJB/8-30

- RH-P600AJB/8-30C

- RH-P600AJB/8-30NP M131 RC

- RH-P600AJB/8-30NP RC

- RH-P64AJ/8-30 IW M131

- RH-P64Q/5

- RH-P64Q/8-30

OGU 051 P3K-TSSL德國DI-SORIC Industrie-electronic光柵

德國di-soric Industrie-electronic GmbH & Co. KG企業集團是一家專業從事標準和特殊傳感器開發和生產的公司, 致力于提供工業自動化產品的應用方案和技術支持。公司擁有29 年多的成功行業經驗,如今已成為全球最大的傳感器生產商之一。 今天,已經有超過180 名員工為德國di-soric公司工作。 公司總部位于德國斯圖加特東部城市 Urbach 。研發及生產的工作由位于多特蒙德南方城市Lüdenscheid的工廠負責。僅在德國就有上千家的客戶正在使用di-soric的產品。 產品介紹:DI-SORIC Industrie-electronic GmbH & Co. KG光柵、DI-SORIC Industrie-electronic GmbH & Co. KG 光纖、DI-SORIC Industrie-electronic GmbH & Co. KG 發射器、DI-SORIC Industrie-electronic GmbH & Co. KG 接收器、DI-SORIC Industrie-electronic GmbH & Co. KG 轉換器、DI-SORIC Industrie-electronic GmbH & Co. KG 傳感器、DI-SORIC Industrie-electronic GmbH & Co. KG 放大器、DI-SORIC Industrie-electronic GmbH & Co. KG 感應開關、DI-SORIC Industrie-electronic GmbH & Co. KG 光纖開關、DI-SORIC Industrie-electronic GmbH & Co. KG 光電開關、DI-SORIC Industrie-electronic GmbH & Co. KG 液位開關、DI-SORIC Industrie-electronic GmbH & Co. KG 光電管發生器、DI-SORIC Industrie-electronic GmbH & Co. KG 漫反射光電管、DI-SORIC Industrie-electronic GmbH & Co. KG 料位開關、DI-SORIC Industrie-electronic GmbH & Co. KG 探頭、DI-SORIC Industrie-electronic GmbH & Co. KG 電器件、DI-SORIC Industrie-electronic GmbH & Co. KG 電纜、DI-SORIC Industrie-electronic GmbH & Co. KG光纖纜產品類型:DI-SORIC Industrie-electronic GmbH & Co. KG OGU 081 P3K-TSSLDI-SORIC Industrie-electronic GmbH & Co. KG OGU 121 P3K-TSSLDI-SORIC Industrie-electronic GmbH & Co. KG OGU 051 P3K-TSSLDI-SORIC Industrie-electronic GmbH & Co. KG OGL 55/53P2K-IBSDI-SORIC Industrie-electronic GmbH & Co. KG OGL 34/31P2K-IBSDI-SORIC Industrie-electronic GmbH & Co. KG D7C 08 V 03 PSK-TSL DI-SORIC Industrie-electronic GmbH & Co. KG D7C 08 V 03 PSLK DI-SORIC Industrie-electronic GmbH & Co. KG D7C 08 V 06 PSK-TSL DI-SORIC Industrie-electronic GmbH & Co. KG D7C 08 V 06 PSLK DI-SORIC Industrie-electronic GmbH & Co. KG D7C 12 V 02 PSK-IBSL DI-SORIC Industrie-electronic GmbH & Co. KG D7C 12 V 02 PSLK DI-SORIC Industrie-electronic GmbH & Co. KG D7C 12 V 04 PSK-IBSL

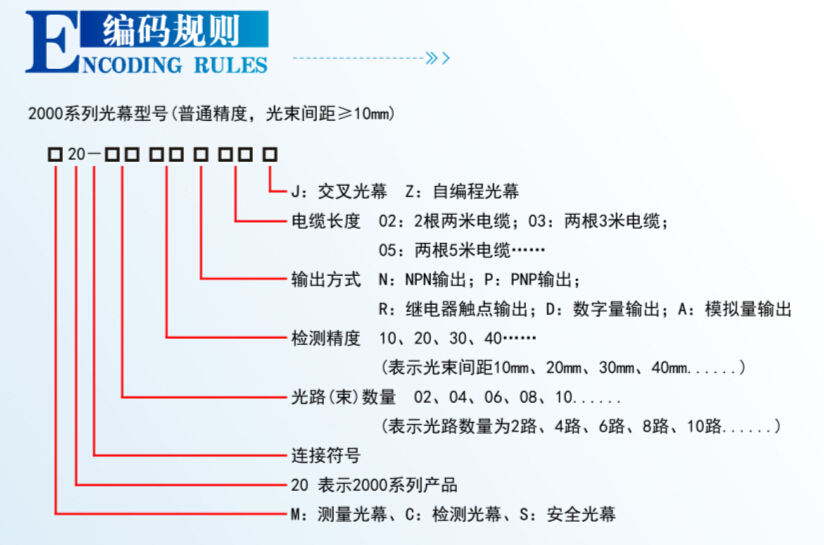

S20-0810安全光柵,安全光幕,檢測光幕,光幕傳感器S2000系列

安全光柵由紅外線發射器和受光器組成,發光器和受光器分別安裝在被檢測區域的兩邊,設備工作時發光器發出紅外光線照射到受光器上,形成一排光幕。當光幕被遮擋,受光器檢測到某路光強度變化后,即可判斷出有異物進入光幕傳感器設定的危險區域,立刻輸出控制信號,通過電纜傳輸到生產設備控制器,控制器控制設備實現停止運行或防止誤啟動的目的。

S20-0810型號表示該產品屬于S2000系列,分辨率為10mm,由8路間距10mm的紅外線組成。

產品安裝高度:145mm;

產品檢測高度:70mm;

kingsensor安全光柵用途:適用于各式沖床、油壓機、剪切機、自動化設備等具有危險性設備、各種大面積區域的安全防護、人體探測感應對人體的安全保護;安裝紅外線保護裝置,檢測到有人員身體進入危險區域即可控制自動停機達到保護人身安全目的。

肯森斯安全光柵有多種規格可供用戶選擇:Kingsensor S2000安全光柵保護器系列:手指探測可選10mm光束間距為分辨率的產品;光束數量可選-8、16、24、32、40、58、56……N束等手掌探測可選20mm光束間距為分辨率的產品;光束數量可選-4、8、12、16、20、24、28……N束等手臂探測可選40mm光束間距為分辨率的產品;光束數量可選-2、4、6、8、10、12、14、16……N束等注明:其它非標準間距和光束數量均可定制。

安全光柵保護器高度:80mm~3000mm均可定制。安全光柵保護器距離:0~3米、0~6米、0~12米可選。

安全光柵保護器信號輸出方式:開關量(繼電器NO、NC,晶體管NPN、PNP),數字量(RS485數據接口)、模擬量(電壓、電流)等。安全光柵狀態指示及故障報警功能:通過LED燈指示光幕工作狀態,同時系統有自檢故障報警功能,根據數碼管故障代碼判斷故障。對于光幕傳感器在故障時,指示燈閃爍報警,同時一直保持保護狀態,鎖死機床等待維修。 安全光柵抗保護器干擾能力強:對電磁干擾,頻閃燈光、焊接弧光、日光燈、太陽光等光源有良好的抗干擾能力。

光幕傳感器防撞擊、抗震性強:有多項防撞抗震措施保護產品不受破壞。 防塵設計:密封設計,防護等級IP65。 安全光柵保護器功能多樣化:可用作人身保護、物體檢測、尺寸測量、和其它特殊用途,可定制。

附:光幕傳感器的精細選型以及技術參數詳情請致電本公司或者登錄本公司網站選型指南。

DA 7200連續光譜固定光柵近紅外分析儀

SMW-GSCSMW-GSC光柵位移傳感器 自復位探頭光柵尺

光柵尺定義:

光柵尺通過摩爾條紋原理,通過光電轉換,以數字方式表示線性位移量的高精度位移傳感器。光柵線位移傳感器主要應用于直線移動導軌機構,可實現移動量的精確顯示和自動控制,廣泛應用于金屬切削機床加工量的數字顯示和CNC加工中心位置環的控制。該產品已形成系列,供不同規格的各類機床選用,量程從10毫米至30米,覆蓋幾乎全部金屬切削機床的光柵電子尺,光柵尺,銑床電子尺,車床電子尺,光柵線位移傳感器。

光柵尺參數:

柵距:0.01mm(100線對/mm)、0.02mm(50線對/mm)、0.04mm(25線對/mm)

精度:±0.008mm、±0.01mm、±0.015mm、(20℃ 1000mm)

響應速度:60m/min(0.005mm) 25m/min(0.001mm)

測量范圍:10mm~30000mm以內任意選擇

分辨率為:0.5u-1u-5u-10u-25u

輸出訊號:TTL方波、HTL方波、RS422信號、正弦電壓信號1Vp

供應電壓:5V、12V、15V、24V

參考標記:間隔25mm、50mm、100mm、200mm、或全行程任意位置設一個絕對位置參考點(ABS)

工作溫度:0-55℃ 存儲溫度:-40℃-55℃

光柵尺主要應用:

1、各類測量機構、儀器的位移測量:彈簧試驗機、三坐標機、投影儀

2、各類機床的數顯系統:車床、銑床、磨床、鏜床、電火花、精密儀器等

3、各類數控機床的配套使用:數控銑、加工中心、數控磨等

4、配接PLC,用于各類自動化機構的位移測量.

產品特點:1、最先進的光學測量系統,采用可靠耐用的高精度五軸承系統設計, 保證光學機械系統的穩定性,優異的重復定位性和高等級測量精度。

2、傳感器采用密封式結構,性能可靠,安裝方便。

3、采用特殊的耐油、耐蝕、高彈性及抗老化塑膠防水,防塵優異,使用壽命長。

4、具體高水平的抗干擾能力,穩定可靠。

5、光源采用進口紅外發光二極管,體積小壽命長。

6、信號線采用多層隔離線網及金屬軟管保護,防水及抗干擾性能優良

7、采用先進的光柵制作技術,能制作各規格的高精度光柵玻璃尺。

深圳市斯銘威科技有限公司,聚生產銷售一體化廠家,廠家原裝配套儀表,可定制非標!歡迎來電來函SR193i193mm焦距高光通量影像校正光柵光譜儀-SR193i

- 主動聚焦追蹤,根據光柵不同的衍射角或者不同的光柵自動調整聚焦鏡的位置以保證最佳分辨率

- 自動聚焦,無需手動調整,僅需要點下按鈕即可實現最好的分辨率

- 精密的索引和容易使用的艙口設計,可現場升級

- 自動的光柵識別和光柵參數讀取

- 在軸掃描

- 通過和單點探測器使用光譜范圍可拓展至12um

- 可作為可調諧光源分光器件

- 可調高度的墊腳以及可供選擇連接光譜儀的直接C口接口,透鏡接口和籠式接口

- 15mm寬度的動態狹縫拓展的成像區域和光譜分析可通過同一光路得到

- 同一軟件平臺可同時控制ANDOR相機、光譜儀和大量顯微鏡以及附件

- 專用的,容易使用的光譜處理界面

newfiber光纖光柵水位計|激光水位計|安全穩定免維護

WDS-4C型組合式多功能光柵光譜儀WDS-4C型

【商品簡介】

WDS-3型組合式多功能光柵光譜儀

組合式多功能光柵光譜儀規格參數:波長范圍:200-800nm焦距:300nm相對孔徑:D/F=1/7光柵條數:1200L/mm或600/mm雜散光:≤0.3%T波長精度:±0.4nm外型尺寸:370*280*200(mm)狹縫:寬度0-2mm連續可調 示值0.01mm/格 最大寬度20nm 譜線半寬度:波長在589出狹縫高3mm 寬0.2mm譜線半寬度 ≤0.2nm接收單元:光電倍增管接口:USB

WDS-4型組合式多功能光柵光譜儀 組合式多功能光柵光譜儀規格參數:焦距:300mm相對孔徑:D/F=1/7雜光度:≤0.3%T分辨率:在300nm處可分辨聚苯乙烯七個峰(透過率方式)接收單元:TGS熱釋電探測器、硫化鉛探測器、鎘汞光探測器等接口:USB外形尺寸:370*280*200(mm)| 型號 | 波長范圍(nm) | 閃耀波長(nm) | 波長精度(nm) | 波長重復性(nm) | 光柵條數(L/mm) |

| WDS-4 | 800-1500 | 750 | ±2 | 1 | 600 |

| WDS-4A | 1000-3000 | 1400 | ±4 | 2 | 300 |

| WDS-4B | 2500-5000 | 5000 | ±6 | 3 | 100 |

| WDS-4C | 2500-15000 | 雙閃耀 | ±8 | 4 | 66 |

威海迪控廠家優惠價格角度轉速線速度位移光柵數顯表頻率表DK900

◆威海迪控DK900角度儀產品說明:

1、該儀表用于測量角度,具有倍率輸入和外部編輯、復位功能,及全自動計數功能。2、角度顯示分辨率取決于傳感器分辨率,角度變換系數由用戶隨意設定3、當前計數值和設定值掉電不消失。4、設定兩個控制值,兩路繼電器輸出和控制。5、可給外接傳感器提供5V、12V電壓6、可設定倍率,顯示值達到理想顯示方式。

威海迪控DK900型光柵表是一個六位顯示的位置、控制、顯示模塊。可廣泛應用于工業控制領域。◆國際通用96×48×112mm標準機箱,六位0.56英寸數碼管顯示。◆輸入1和輸入2構成雙輸入端,可識別相位為90度的脈沖編碼器信號。◆設定兩個控制值,兩路繼電器輸出、控制或報警。◆可選4種繼電器輸出方式◆可設定自動延時復位時間,實現自動延時復位功能◆峰值顯示功能◆參數設定密碼保護功能◆當前計數值、設定值掉電不丟失◆可設定倍率,確定輸入脈沖與顯示值之間的比例關系。◆外接傳感器:角、線位移光柵傳感器,給傳感器提供5V(100mA)、12V(30mA)電壓。◆計數倍率:單倍頻、雙倍頻、四倍頻可選◆可設定差補值

◆技術參數1、供電電源:220V 50HZ 2、輸入電阻:20K 3、脈沖頻率:不大于30K4、倍率范圍:0.00----1655、顯示范圍:-199999——+9999996、脈沖電平:低電壓—50V--0.5V 高電壓4V——50V7、安裝方式:卡入式8、顯示器尺寸:48*969、開孔尺寸:92*44◆選型指南1、傳感器顯示分辨率以度為單位,2、顯示精確到小數點后3位數,就是0.001度3、為了提高實際測量精度,選用高線數的編碼器,或采用倍比轉換4、傳感器的型號選擇請根據現場的使用情況開選擇,配件根據傳感器型號選擇。5、傳感器常用線數以360線、900線、1800線、3600線、5000線為主。6、傳感器選用與顯示器匹配的輸出形式和供電電源。

最新產品

- EMS低粘度包埋樹脂套裝14300 2025/7/8 11:44:13

- H-L-Lys(N3)-OH·HCl,一種在生物化學和生物學研究中廣泛應用的點擊化學試劑 2025/7/8 11:42:59

- N-(4E)-反式環辛烯-L-賴氨酸,可用于制備功能性納米材料或作為改性劑 2025/7/8 11:35:44

- 導軌式多功能電能表 2025/7/8 11:34:57

- 投入式液位變送器 2025/7/8 11:34:21

- 投入式液位變送器 2025/7/8 11:33:42

- 投入式液位變送器 2025/7/8 11:32:41

- 桔光三代足膝寶 內透熱超短波養生艙 調理老寒腿靜脈曲張設備 2025/7/8 11:30:06

- NHS-C15-COOH,可以作為表面修飾劑或功能化試劑 2025/7/8 11:28:14

- 汽車模擬振動臺全功能振動試驗臺 2025/7/8 11:26:32

- 投入式液位變送器 2025/7/8 11:26:30

- 投入式液位變送器 2025/7/8 11:25:10

- ZCJD-ZK接地阻抗測試儀 2025/7/8 11:24:54

- 投入式液位變送器 2025/7/8 11:24:02

- 投入式液位變送器 2025/7/8 11:22:43

- 琥珀酰亞胺酯-C16-羧酸,可以作為蛋白質或多肽的標記試劑 2025/7/8 11:21:33

- 投入式液位變送器 2025/7/8 11:21:27

- ZCCD-B接地線成組電阻測試儀 2025/7/8 11:20:03

- 投入式液位變送器 2025/7/8 11:19:41

- 維修德國EA大電流實驗室直流電源 2025/7/8 11:17:00

- ZCCD-A接地線成組電阻測試儀 2025/7/8 11:14:41

- 投入式液位變送器 2025/7/8 11:13:55

- 6-fam-OtBu,1845691-47-5,屬于熒光素(Fluorescein)類衍生物 2025/7/8 11:11:53

- 投入式液位變送器 2025/7/8 11:11:31

- sop封裝淋雨試驗箱工業淋雨試驗箱淋雨模擬試驗箱淋雨環境模擬測試設備 2025/7/8 11:11:08

- 豚鼠丙酮酸脫氫酶E1(PDH E1)酶聯免疫試劑盒 2025/7/8 11:10:57

- 豚鼠胰蛋白酶原激活肽(TAP)酶聯免疫試劑盒 2025/7/8 11:10:15

- 投入式液位變送器 2025/7/8 11:10:06

- 穩定性試驗冷熱沖擊試驗箱順德實驗室高低溫沖擊箱汽車LED專用冷熱沖擊箱高低沖擊試驗箱 2025/7/8 11:10:05

- CTP-A1變頻互感器綜合測試儀 2025/7/8 11:09:37